In our DMK Sustainability Strategy 2030, we aim to reduce our emissions of CO2 and are championing innovative projects for a greener future.

At DMK, we have set out on a sustainable journey: Our goal is to emit less CO2 and thereby make an active contribution to environmental protection. Our CO2 emissions came to 8.8 million tonnes in 2020. That sounds like a lot, but compared to other companies our CO2 footprint per kilo of milk is only 1.07 kilos – a low figure for our industry.

However, it isn’t low enough for us. We have therefore undertaken in our Sustainability Strategy to reduce all greenhouse gas emissions by at least 20% by 2030 – to 7 million tonnes.

Our flagship project: less CO2 in our own production.

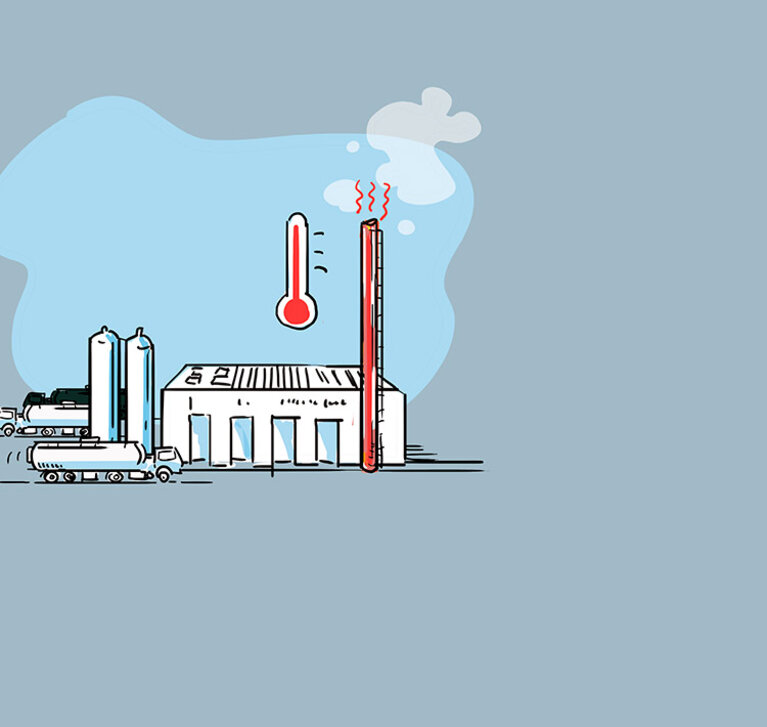

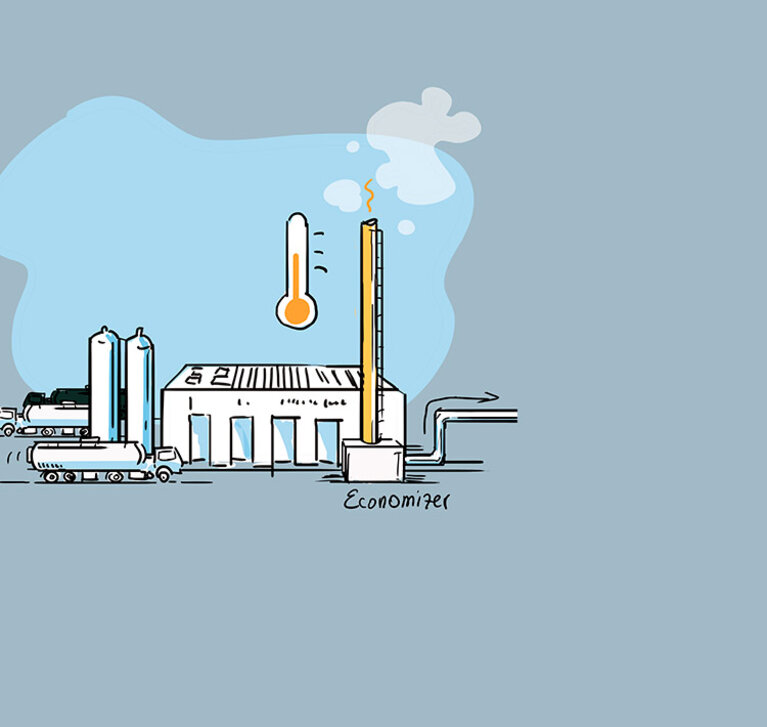

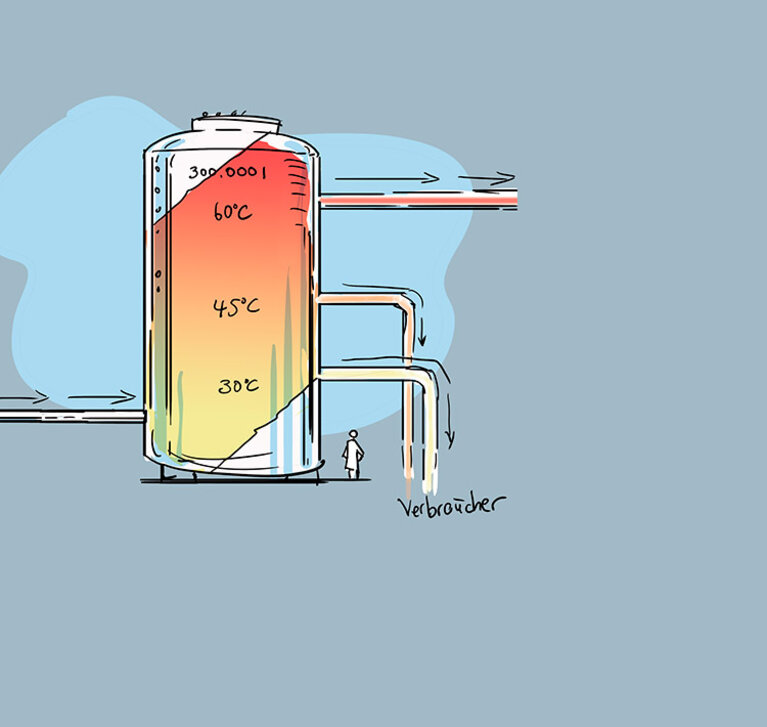

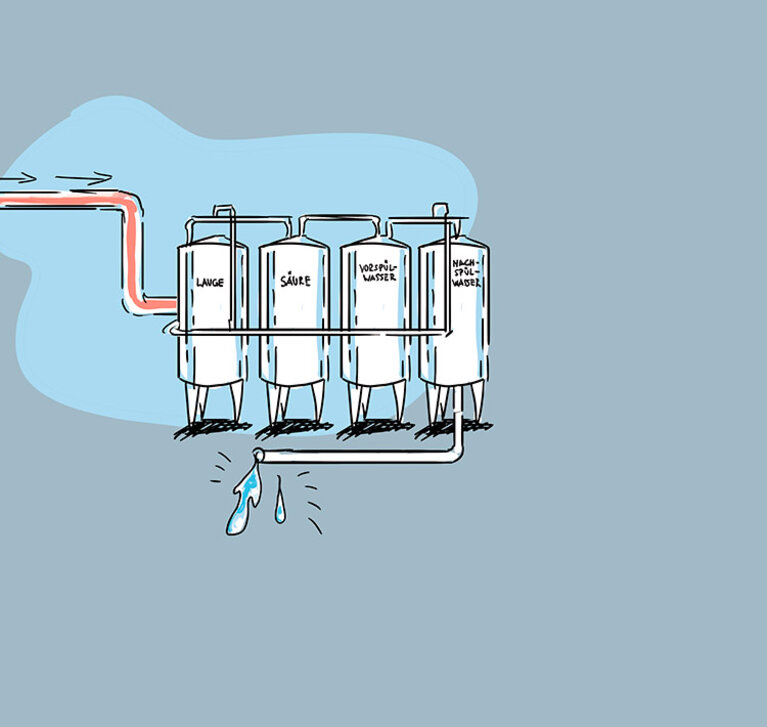

Our production at DMK only contributes around 5% of the total CO2 emissions in the dairy value chain. However, that doesn’t stop us from doing something in this area. In particular, the heat generated by natural gas causes a large part of our emissions. We are therefore pursuing a clever approach at our Edewecht factory:

By using waste heat and linking heat sources and heat sinks intelligently, we can save around 4,500 tonnes of CO2 every year, which is equivalent to reducing natural gas consumption by a good 10% per year. Our site was even honoured as a flagship project by the German Energy Agency (dena) in the year 2020.

But that’s not all – our biomass heating plant in Waren is another opportunity. We use wood chips instead of fossil fuels such as gas there, enabling us to save around 2,500 tonnes of CO2 per year compared to gas.

Only natural timber is used for the biomass. This consists of wood and wood components that occur in agriculture, forestry and horticulture or in the care and maintenance of the countryside, such as tree and shrub prunings, forest thinnings and logging waste. A maximum volume of fuel of approx. 8100 tonnes can be used every year.

![[Translate to English:] [Translate to English:]](https://dmk.de/fileadmin/_processed_/e/7/csm_DMK_28A5636_45c62fc95c.jpg)

![[Translate to English:] [Translate to English:]](https://dmk.de/fileadmin/_processed_/d/2/csm_K%C3%BChe_auf_der_Weide_7e4f85b32c.jpg)